Photo by Opt Lasers from Poland on <a href="https://www.pexels.com/photo/close-up-shot-of-cnc-lasers-7254428/" rel="nofollow">Pexels.com</a>

Photo by Opt Lasers on Unsplash

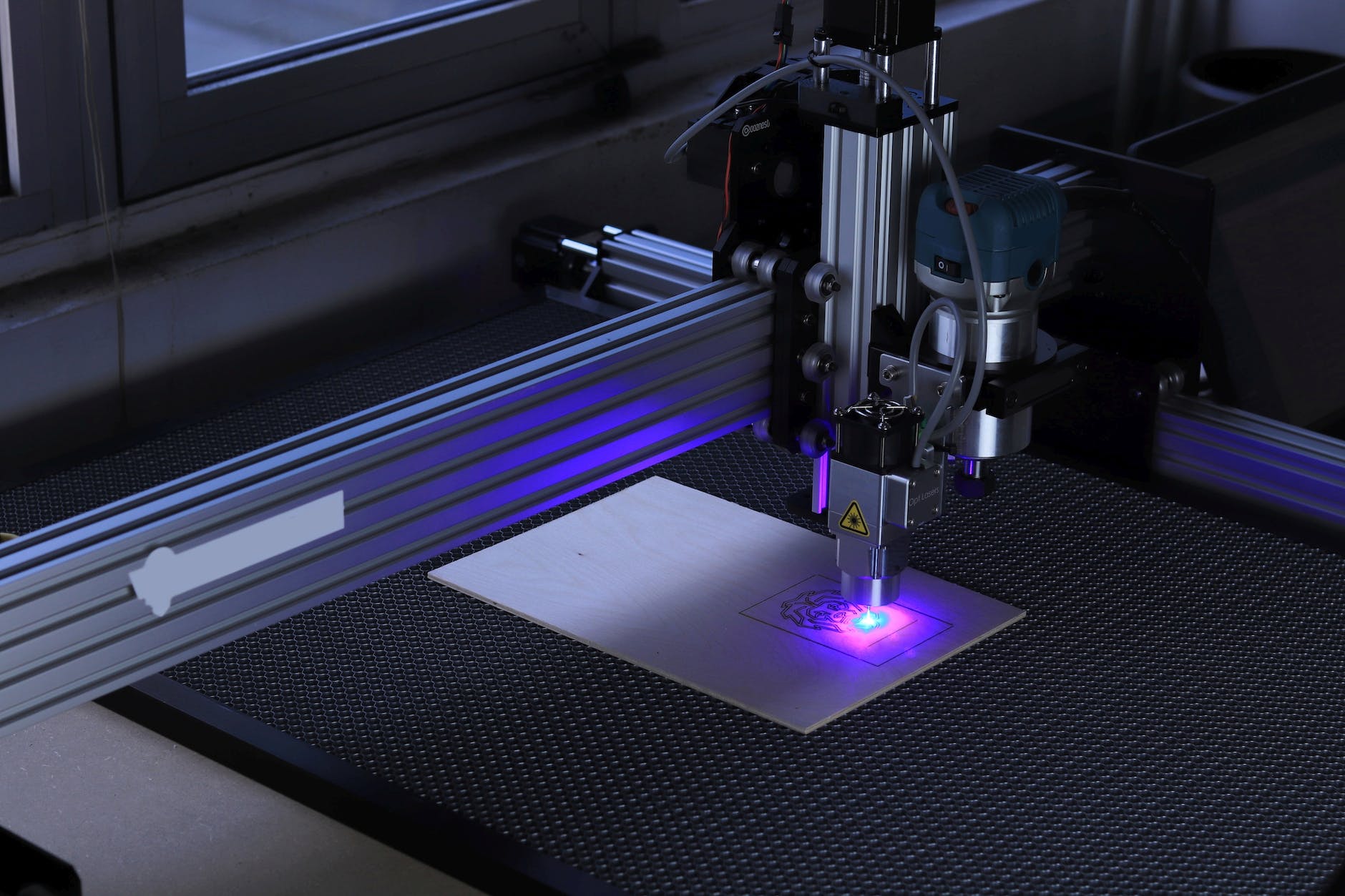

Machines that are controlled by a computer and follow a set of instructions stored in a computer are called computer numerical control (CNC) machines, and they are used extensively in the manufacturing industry. Although technology can make the workplace safer by decreasing the need for human intervention, you should nonetheless be aware of the risks they can represent and take steps to minimize those risks.

Humans Should Still Be Involved

CNC machines are great for cutting down on manufacturing-related human work, but that doesn’t mean you should leave them unattended. The possibility of failure, however small, remains. At some point, humans will have to engage with CNC machines, and if problems aren’t spotted in time, they could cause further damage to the machine or even harm to the worker. Therefore, you should always have someone who is familiar with CNC machines and their common problems such as inappropriate tools, faulty programming, and chatter/vibration watching over them. If you Buy used CNC machines you will also need a human being to check they are in the best condition.

Any User Should Be Trained

While computer numerical control (CNC) machines can complete many tasks with little to no human intervention, you should still restrict access to individuals who have received the proper training and have the appropriate experience and skills to operate them. Investing in CNC training for your employees is one way to ensure that they arrive at work prepared to work safely.

Make Sure They Are In A Safe Space

Clear the space around a CNC machine, and make sure your employees know not to go near the machines while they are still powered on. Machine guards should be installed on all CNC machines, and the doors should be kept shut at all times while they are in use, in addition to ensuring that employees are instructed to avoid attempting to rectify jams or improper positions.

Make Sure You Invest In Replacements And Maintenance

CNC machines are expensive to purchase, maintain, and repair due in large part to the high quality of the components it requires. Invest as much as the manual instructs in CNC machine maintenance, and replace worn parts with new, high-quality ones. If you don’t, you run the risk of dangerous and expensive machine failure in the future.

Look Out For Your Employees

If machine workers are fatigued or in pain, the risk of an accident or injury increases dramatically. Workplace ergonomics and a schedule that allows for frequent breaks can help keep employees healthy and lessen the likelihood that they will experience physical stress that can lead to errors. Preventing workers from having to repeatedly bend over or reach for objects is a common ergonomics goal in production.

If you take CNC machines seriously, they can save you a lot of money in your production processes. We hope that the aforementioned suggestions have demonstrated this.